What is an Energy Audit?

An energy audit is a comprehensive review of how energy is used throughout a building or facility. The goal is simple: find where energy is being wasted and recommend improvements to reduce that waste. It helps businesses save money, improve efficiency, and reduce their environmental impact.

Energy audits typically include:

- Reviewing past electricity, gas, or fuel bills

- Walking through the site to observe energy-consuming equipment

- Using tools to measure how much energy systems are using

- Identifying specific issues like overuse, outdated technology, or poor insulation

There are three levels of energy audits:

- Walkthrough Audit: A basic assessment to identify glaring inefficiencies.

- General Audit: data analysis, measurements, and practical solutions.

- Investment-Grade Audit: A deeper dive, often used before large investments or upgrades.

In today’s high-cost energy environment, businesses can no longer afford to ignore hidden energy waste. From idle machines to unnoticed air leaks, inefficiencies silently add up to significant losses. A professional Energy Audit can uncover these hidden drains and guide your organization toward smarter, more sustainable energy practices.

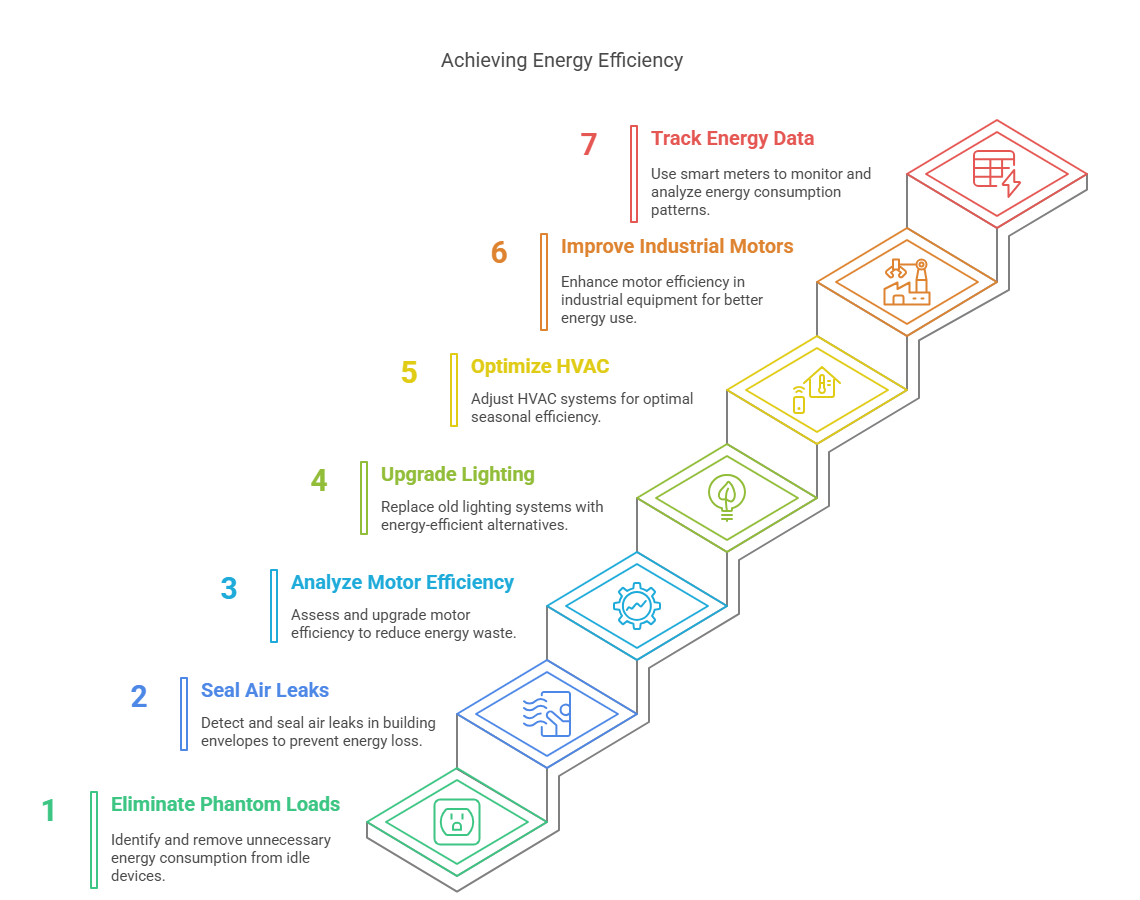

Here are 7 actionable energy audit tips to help you cut down on waste and boost efficiency:

1. Identify and Eliminate Phantom Loads

Phantom loads, also known as vampire power or standby power, refer to the energy consumed by electronic devices even when they appear to be turned off. These include appliances and equipment like:

- Monitors and printers in standby mode

- Chargers plugged in without connected devices

- Coffee makers with digital displays

- Microwave ovens with clocks

- Network devices like routers or modems left on 24/7

While each device may only draw a small amount of electricity, the cumulative effect across a facility or office space can be substantial, adding up to thousands of kilowatt-hours annually.

How to Detect Phantom Loads:

- Plug Load Meters: Use watt meters to measure how much energy individual devices use when idle.

- Energy Audits: Conduct walk-through inspections during non-operating hours to identify equipment still drawing power.

- Sub-metering: Install plug-level or circuit-level sub-meters to track energy use patterns and isolate idle consumption.

How to Eliminate Them:

- Unplug Unused Devices: Especially overnight or during weekends.

- Install Smart Power Strips: These can cut power to devices that enter standby mode.

- Use Timers or Occupancy Sensors: Automatically shut down non-essential equipment after hours.

- Centralize Control: Implement policies for employees to shut down devices daily or control them via centralized power management systems.

Energy and Cost Savings:

Phantom loads can account for 5–10% of electricity usage in commercial buildings. Eliminating them is a quick win, no major investment needed, just awareness and routine updates in device management.ge and provide alerts when unusual consumption patterns are detected.

2. Detect and Seal Air Leaks in Building Envelopes

Air leaks in a building’s envelope, the physical barrier between the interior and the exterior , can lead to significant energy loss. When uncontrolled outside air enters or conditioned air escapes, HVAC systems work harder to maintain indoor temperatures, driving up energy consumption and utility costs.

Common Leak Points:

- Gaps around doors and windows

- Wall penetrations (cable, piping, vents)

- Poorly sealed ductwork

- Attic hatches and ceiling fixtures

- Baseboards and sill plates

- Electrical outlets on exterior walls

How to Detect Air Leaks:

- Blower Door Testing: A professional diagnostic tool depressurizes the building to locate infiltration points.

- Thermal Imaging Cameras: Identify temperature variations that reveal hidden leaks.

- Smoke Pencils or Incense Tests: Watch airflow changes near suspect areas during HVAC operation.

- Manual Inspection: Feel for drafts on cold or windy days along walls, floors, and openings.

Sealing Techniques:

- Weatherstripping: Apply to doors and operable windows for tight seals.

- Caulking: Seal cracks and gaps around stationary parts like frames, pipes, and vents.

- Foam Sealants: Expand to fill larger gaps around wall penetrations and plumbing.

- Duct Sealing: Use mastic or UL-rated tapes to stop air leakage in duct systems.

- Window Films or Storm Windows: Add layers to improve insulation on older glass installations.

Energy and Cost Impact:

Air leakage can waste 15–30% of heating and cooling energy in commercial buildings. Sealing leaks not only reduces HVAC runtime and utility costs but also improves comfort, indoor air quality, and building lifespan.

3. Analyze Motor Efficiency and Upgrade Equipment

Electric motors are the workhorses of industrial and commercial operations , powering HVAC systems, pumps, compressors, fans, conveyors, and more. However, aging, oversized, or poorly maintained motors often consume far more electricity than necessary, making them a key focus during an energy audit.

Common Motor Efficiency Issues:

- Oversized Motors: Many facilities install motors larger than needed, leading to underloading and poor efficiency.

- Old Motor Designs: Motors that are 10–15 years old typically operate at lower efficiency than today’s premium models.

- Inadequate Maintenance: Dirty, unlubricated, or misaligned motors cause friction, overheating, and wasted energy.

- Poor Power Quality: Voltage imbalances or harmonics can increase operating costs and reduce motor lifespan.

What to Assess During the Audit:

- Load Matching: Compare motor capacity to actual load requirements.

- Operating Hours: Identify motors that run continuously but don’t need to.

- Power Factor: Evaluate how effectively electrical power is converted into usable work.

- Motor Inventory: Create a database with specifications, efficiency class, and condition for each motor.

Upgrade Recommendations:

- Install High-Efficiency Motors (IE3 or IE4): These motors deliver energy savings of 2–8% over standard models.

- Use Variable Frequency Drives (VFDs): VFDs adjust motor speed to match demand, reducing energy use in variable-load applications.

- Implement Soft Starters: Reduce inrush currents and mechanical stress, extending motor life.

- Schedule Preventive Maintenance: Regular checks for alignment, lubrication, and cleaning can preserve efficiency.

Energy and Cost Impact:

Motor systems often account for up to 70% of industrial electricity usage. Upgrading inefficient motors and optimizing their operation can lead to energy savings of 20–40%, while also reducing maintenance needs and unplanned downtime. detected early.

4. Upgrade to Energy-Efficient Lighting Systems

Lighting accounts for a significant portion of energy consumption in commercial buildings, warehouses, and industrial facilities , often as much as 20–40% of total electricity use. Outdated lighting systems not only waste energy but also increase cooling loads due to excess heat. An energy audit helps identify lighting inefficiencies and suggests modern alternatives that cut costs and improve visual comfort.

Common Lighting Inefficiencies:

- Use of Incandescent or Fluorescent Bulbs: These have short lifespans and convert most energy into heat, not light.

- Over-Illuminated Areas: Excessive lighting in low-traffic zones leads to unnecessary energy usage.

- Manual Controls: Lights left on in unoccupied rooms or during daylight hours waste energy.

- Lack of Zoning or Task Lighting: Uniform lighting across the facility, regardless of need, leads to inefficiency.

Audit Recommendations for Lighting:

- Conduct a Lighting Inventory: Record bulb types, wattages, usage patterns, and locations.

- Measure Light Levels (lux): Ensure lighting levels meet task requirements without overuse.

- Evaluate Usage Schedules: Identify zones where lights remain on unnecessarily.

Upgrades That Save:

- Switch to LED Technology: LEDs use 50–80% less energy than traditional bulbs and last up to 25 times longer.

- Install Motion Sensors and Daylight Harvesting Systems: These automatically adjust lighting based on occupancy and natural light availability.

- Implement Smart Lighting Controls: Use timers, dimmers, and building automation systems to optimize energy use.

- Use Task Lighting: Focus light only where it’s needed (e.g., workstations) instead of entire zones.

Energy and Financial Impact:

By replacing inefficient lighting with LEDs and integrating smart controls, businesses can typically reduce lighting-related electricity consumption by 30–60%. In addition, maintenance costs drop significantly due to longer bulb lifespans and fewer replacements.

5. Optimize HVAC Systems for Seasonal Efficiency

Heating, ventilation, and air conditioning (HVAC) systems are often the largest energy consumers in both commercial and industrial facilities , sometimes responsible for 40–60% of total energy use. When these systems are outdated, improperly sized, or poorly maintained, they not only inflate utility bills but also create inconsistent indoor environments. An energy audit helps diagnose these inefficiencies and uncovers key opportunities for savings through seasonal optimization.

Common HVAC Inefficiencies:

- Dirty Filters and Coils: Reduce airflow and force the system to work harder.

- Incorrect Thermostat Settings: Lead to energy waste when cooling or heating unoccupied spaces.

- Outdated Equipment: Older units often operate at low efficiency and lack modern controls.

- Simultaneous Heating and Cooling: Caused by poorly managed zone settings or building automation issues.

Audit Checks Include:

- System Sizing Review: Ensures HVAC equipment matches building load demands.

- Seasonal Performance Evaluation: Measures how HVAC performs in both summer and winter conditions.

- Thermal Imaging: Identifies duct leaks, poor insulation, and overheated equipment.

- Controls and Scheduling Assessment: Checks how well the system responds to time-of-day and occupancy changes.

Optimization Strategies:

- Regular Preventive Maintenance: Clean filters, inspect ductwork, and calibrate thermostats.

- Smart Thermostats and Zoning: Automate temperature controls based on time, occupancy, and area usage.

- Install Variable Speed Drives (VSDs): For motors and fans to adjust output according to actual demand.

- Seasonal Commissioning: Recalibrate systems at the beginning of cooling and heating seasons to align with external temperature variations.

Energy and Financial Impact:

HVAC optimization can lead to 15–30% reductions in energy consumption and significantly extend the lifespan of equipment. Proper controls and maintenance also enhance indoor air quality and occupant comfort, contributing to better employee productivity and fewer complaints.

6. Improve Motor Efficiency in Industrial Equipment

Electric motors are the workhorses of industrial operations, driving pumps, fans, conveyors, compressors, and more. But without proper management, they can also become silent energy wasters. Inefficient, oversized, or poorly maintained motors consume significantly more electricity than needed. An energy audit allows you to assess motor performance and uncover actionable opportunities for cost savings.

Common Issues Identified During Audits:

- Operating Motors at Constant Speed: When load varies, fixed-speed motors waste energy.

- Oversized Motors: Motors too large for their application run at partial load, operating inefficiently.

- Worn Bearings or Misalignment: Increases mechanical friction and reduces lifespan.

- Unscheduled Maintenance: Leads to breakdowns, inefficiencies, and unexpected downtime.

- Low Power Factor: Indicates excess reactive power consumption, increasing utility costs.

Energy Audit Recommendations Often Include:

- Motor Inventory and Load Assessment: Determines if motors are running underloaded or are improperly sized.

- Power Quality Analysis: Identifies voltage imbalances, harmonics, and poor power factor.

- Thermal Imaging and Vibration Monitoring: Detects overheating, alignment issues, and early signs of failure.

- Run-Time and Duty Cycle Monitoring: Helps match motor performance with actual usage patterns.

Optimization Solutions:

- Upgrade to Premium Efficiency Motors: These meet or exceed IE3/IE4 efficiency standards and can cut energy use by 2–8%.

- Install Variable Frequency Drives (VFDs): Allows motors to run at the required speed, improving efficiency up to 50% in variable load applications.

- Implement Predictive Maintenance: Use sensors and monitoring tools to schedule servicing before failures occur.

- Power Factor Correction: Install capacitors or synchronous condensers to reduce utility penalties and optimize performance.

Example Outcome:

Switching to high-efficiency motors and adding VFDs in a medium-sized manufacturing facility led to an annual energy saving of 120,000 kWh, translating to over PKR 2 million saved in utility costs and a 20% reduction in downtime due to proactive maintenance.

7. Track and Analyze Energy Data with Smart Meters

You can’t manage what you don’t measure. One of the most powerful tools in an energy audit is real-time energy data, and smart meters are the key to unlocking it. Traditional utility bills only show a summary, often missing peak demand times, daily trends, or equipment-level consumption. Smart energy meters and submetering systems provide granular, actionable data to optimize performance and reduce waste.

Why Smart Metering Matters:

- Real-Time Monitoring: Know exactly how much energy is being used, when, and where.

- Load Profiling: Identify patterns in energy consumption across shifts, departments, or machines.

- Anomaly Detection: Spot sudden spikes or unusual consumption that may indicate equipment faults or leaks.

- Peak Demand Identification: Helps reduce demand charges and shift loads strategically.

Audit Insights Enabled by Smart Meters:

- Pinpoint energy hogs during off-peak hours or idle times.

- Highlight inefficient operational practices like lights and HVAC running during unoccupied periods.

- Reveal overlapping loads that cause demand spikes and inflated utility bills.

Recommended Actions:

- Install Main and Sub-Meters: Measure total facility consumption as well as key systems like HVAC, lighting, and motors.

- Integrate with an EMS (Energy Management System): Create dashboards for live energy visualization and automated reporting.

- Set Threshold Alerts: Receive notifications when usage crosses optimal limits or patterns deviate from the norm.

- Benchmark and Compare: Track performance over time or against similar facilities to identify improvement areas.

Real-World Benefit:

A textile unit equipped with Daitan’s EMS and smart sub-metering reduced energy wastage by 15% in under 90 days. By identifying unexpected spikes in HVAC and compressor loads, they adjusted schedules and saved over PKR 1.5 million annually in electricity costs.

How Daitan Solutions Can Help You Maximize Energy Efficiency

At Daitan Solutions, we specialize in uncovering hidden energy inefficiencies and transforming them into measurable operational improvements. Through our advanced tools, expert audits, and industry-specific strategies, we help organizations achieve both financial and environmental goals.

Comprehensive Energy Audit Services

We offer tailored energy audits based on your facility’s size, complexity, and needs:

- Walkthrough Audits for identifying quick wins and low-cost opportunities.

- Detailed (General) Audits using data-driven tools to quantify inefficiencies.

- Investment-Grade Audits for organizations planning capital upgrades or pursuing performance contracts.

Our audits cover all major systems, including HVAC, lighting, motors, electrical panels, building envelope, and process equipment.

Advanced Diagnostic Tools and Monitoring Technologies

We use state-of-the-art instruments to ensure precise diagnostics and recommendations, including:

- Thermal Imaging Cameras to identify insulation gaps, overheating equipment, and HVAC leaks.

- Power Analyzers and Loggers to detect phase imbalance, voltage drops, and equipment anomalies.

- Ultrasonic Detectors for finding compressed air and gas leaks.

- Flow and Combustion Meters for analyzing pump efficiency, fuel combustion, and HVAC performance.

- Smart Energy Meters and IoT Sensors that feed real-time data into our EMS platform for continuous visibility.

Custom Energy Management Systems (EMS)

Our proprietary, cloud-based EMS platform enables clients to:

- Monitor real-time energy use across devices, buildings, and systems

- Receive alerts for unusual consumption or peak loads

- Generate visual dashboards and reports for decision-making

- Track ROI and verify the impact of energy-saving actions

We help you shift from reactive energy management to a proactive, data-driven approach.

Implementation Support and Optimization

At Daitan, we don’t stop at diagnostics. We work hand-in-hand with your team to execute recommendations and improve energy outcomes:

- Motor right-sizing and VFD integration

- HVAC leak repair and system balancing

- Lighting redesign and automation

- Load redistribution and panel upgrades

- Preventive maintenance programs to avoid future inefficiencies

Our engineers ensure every fix is technically sound, financially viable, and strategically aligned.

ESG and Sustainability Integration

Energy efficiency is no longer optional, it’s a vital part of environmental, social, and governance (ESG) performance. Daitan Solutions helps you:

- Align energy efforts with sustainability goals and green certifications (LEED, ISO 50001)

- Develop and support ESG disclosures with verified energy data

- Position your brand as environmentally responsible to investors, regulators, and customers

Industries We Serve

We bring customized energy solutions to:

- Industrial Facilities & Manufacturing Plants

- Commercial Buildings & Office Complexes

- Retail Chains & Warehousing

- Public Sector Institutions & Hospitals

- Educational Campuses & Data Centers

No matter the sector, we tailor our services to your operational realities and ROI expectations.

Why Choose Daitan Solutions?

- Deep expertise in energy audits and power quality diagnostics

- Cutting-edge tools and technology-backed EMS solutions

- End-to-end support from analysis to implementation

- Measurable savings with most clients achieving energy cost reduction

- Long-term partnerships focused on performance, compliance, and sustainability

Let’s Start Reducing Your Energy Waste

Whether you’re aiming to lower utility bills, extend equipment life, or strengthen your ESG profile, Daitan Solutions is your partner for intelligent energy management.

Book a consultation today:

📩 info@cqm.pme.mybluehost.me

🌐 www.daitansol.com